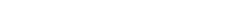

POP Rivet

POP Rivet Specification

- Usage

- Construction

- Product Type

- Pop Rivets(

- Color

- Gray

POP Rivet Trade Information

- Minimum Order Quantity

- 100 Pieces

- Supply Ability

- 5000 Pieces Per Month

- Delivery Time

- 10 Days

About POP Rivet

POP Rivets, also known as Blind Rivets, are fasteners designed for joining two or more materials where access is only available from one side. They are widely used in applications like construction, automotive, aerospace, and manufacturing because of their ease of installation and strong, durable hold.

Key Features:

Blind Installation: Can be installed from one side of the workpiece, making them ideal for applications where the back side is inaccessible.

Materials: Commonly made from aluminum, stainless steel, copper, or steel, offering corrosion resistance and strength.

Components: Consist of a hollow cylindrical shaft (the rivet body) and a mandrel (a pin) which is pulled to expand the rivet body inside the hole, creating a secure fastening.

Variety of Sizes: Available in various diameters and lengths to suit different thicknesses of materials.

Applications: Used in joining sheet metals, plastic panels, leather, and other materials in industries such as automotive, aerospace, electronics, and construction.

Advantages:

Quick and easy to install with a rivet gun.

Provides strong, vibration-resistant fastening.

Suitable for thin or fragile materials.

Available in a wide range of materials for different environments

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Other Products Category

Industrial Washers

Price 100 INR / Piece

Minimum Order Quantity : 100 Kilograms

Color : Silver

Usage : Construction

Product Type : Industrial Washers

Grade : MS

Hex Nut

Price 300 INR / Piece

Minimum Order Quantity : 100 Pieces

Color : Gray

Usage : Construction

Product Type : Hex Nut

Grade : MS

Nylock Nut

Price 150 INR / Piece

Minimum Order Quantity : 100 Kilograms

Color : Gray

Usage : Construction

Product Type : Nylock Nut

Grade : MS

Coach Bolt

Price 200 INR / Kilograms

Minimum Order Quantity : 50 Kilograms

Color : Black

Usage : Industrial

Product Type : Coach Bolt

Grade : A